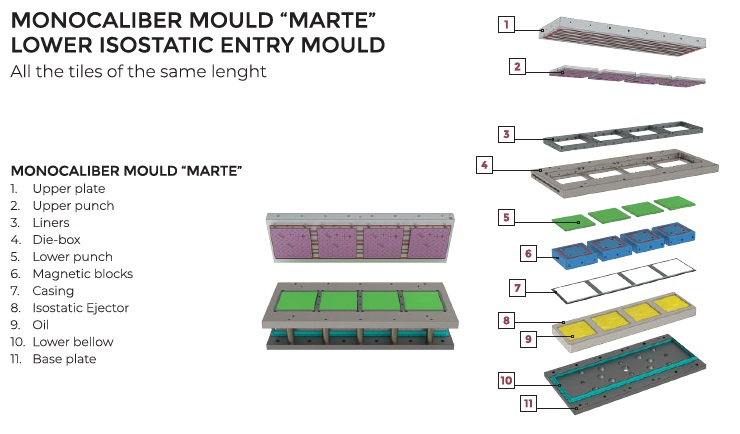

Created because

The evolution of the pressing technique, in terms of finished product, has presented problems that moulds and isostatic punches of the traditional type cannot solve. This has posed the question of creating a product which, in conjunction with the “TREBAX” isostatic punches, could solve the many production problems. The simplicity to regenerate an entering punches mould allows to insert within each existing mould the isostatic part, that is patented and exclusive production of TREBAX.

Uniformity of pressure and density

The entering isostatic punch mould has telescopic and independent magnetic blocks, this allow to have the same density among the cavities of the mould, obtaining numerous advantage on the final product, that means also the safeguarding of the press, since the applied compression strength is evenly spread out and well balanced. The isostatic entering punches mould, combined with the isostatic TREBAX punches, allows the obtaining of the squaring and of the caliber, as the oil of isostatic punch works inside of it – avoiding to the oil to flow from one cavity to the other - in order to obtain equal length of the sides of the single tile (squaring) and the oil of the isostatic entering punch mould works to obtain equal lengths between the various cavities (caliber). On a mould with 4 cavities we have the certainty that all 4 tiles, in view of the uniformity of the applied pressure, though featuring very deep reliefs different from one another, will enter in the same box, as they are of the same length. Due to the different designs is known that cracks can be generated along the tile (expansion cracks). Thanks to this innovative system that let the density in the cavities be uniform, it avoids the creation of these cracks due to the expansion of the tile during the extraction of the same.

Reliability

Thanks to the study of new production systems, the Research and Development of TREBAX Departments have achieved an unique and total reliability level on both the hydraulic system, on both the mechanical movements, that constitute the isostatic TREBAX products . The isostatic entering punches mould has a retained oil system that brings him to be extremely reliable even for the fact that the circuit operates at low pressure and then the efforts of the hydraulic system are extremely low and the circuit, with the exception than recovery pressure, it is entirely internal. In case of abnormal charging of powder the isostatic entering punches mould can be drained from the oil and works as a normal mould without stopping the production. The isostatic entering punches mould, combined with isostatic TREBAX punches, allows to eliminate the connecting pipes, thereby avoiding the possible breakage of the same course, the breaking of the isostatic dies and the consequent production of material out of balance, intended to be downgraded.

Reduce your costs! Reduce your store!

What does it mean, in terms of costs, to produce a single gauge? It means been able to produce the required volume only, necessary for the clearing of the Customer’s order, without producing any surplus that will not be sold, but which will be stocked in the store, with the ensuing unnecessary increase of value.

Technical and economic advantages

1. Mono-caliber. A lower quantity of different calibers in store will inevitably correspond to important economic savings.

2. Connecting pipes of the isostatic punches no longer required, thus avoiding breakages of the same, possible oil leaks and related loss of production (downtime)

3. The isostatic punch works to obtain squaring, the isostatic mould to obtain equal lengths between the various cavities (caliber).

4. Same pressure uniformity on all cavities, that means also the safeguarding of the press, since the applied compression strength is evenly spread out and well balanced.

5. Possibility to manufacture products with moulds featuring multiple rows (ex.: 32 cavities 10x10, 20 cavities 15x15, 14 cavities 20x20, 8 cavities 30x30, 6 cavities 40x40 etc.) with the peace of mind of realizing mono-caliber tiles.

6. Possibility of manufacturing tiles featuring very deep reliefs and differing from one another, with the certainty of placing the tiles in the same box.

7. Production of materials with always differing drawings and structures is a unique commercial advantage and still using a single commercial vehicle.

8. Possibility to apply different options, including long life liners, dust extraction system, floating die-box, magnetism electromagnetic or permanent etc.

9. Possibility to be installed on all the traditional moulds with a simple regeneration.

10. Simplicity of use by the operator since the system does not need any maintenance or adjustment by the operator.