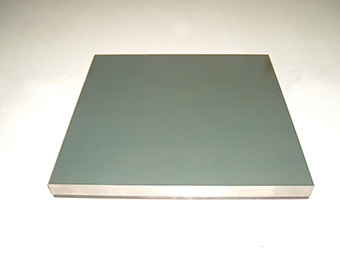

Pattern fitted punch with rubber coating

It is an inexpensive punch featuring great versatility. It is made of special steel, with an all-round electro welded pattern made from a very high wear-resistant material. The anti-washing surface coating made from polymer does not require the use of a brush for the cleaning of the punches. The polymer coating enables the realization of particular complex effects on the surface.

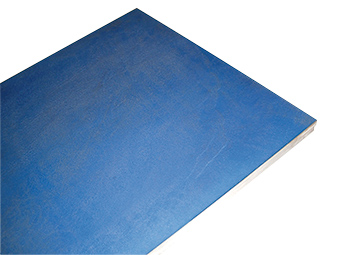

Pattern fitted punch with traditional resin coating, or thin resin coating

It is an inexpensive punch featuring great versatility. It is made of special steel, with an all-round electro welded pattern made from a very high wear resistant material. The anti-washing surface coating made from polymer does not require the use of a brush for the cleaning of the punches. The resin coating enables the realization of a very glossy surface on the finished product, shiny and with little porosity.

Lapped pattern fitted punch

This is made from compound steel, highly resistant to wear. It then undergoes a thermic tempering and hardening treatment, to bring it to the required hardness. The polish will create tiles with high quality surfaces. It is particularly suitable for the production of porcelain stoneware. On the finished product, the polish creates a very similar surface to that of the chromium plated punch, hence very shiny and with little porosity, without the cost of the chromium plating.

Chromium plated pattern fitted punch

This is made from compound steel, highly resistant to wear. It then undergoes a thermic tempering and hardening treatment, to bring it to the required hardness, then it’s chromed it is particularly suitable for the production of porcelain stoneware. The chromium plating is today still the best treatment for a very shiny and low porosity finished product.

Three dimensional shaped pattern fitted punch

This is made from compound steel, highly resistant to wear. It is particularly suitable for the production of porcelain stoneware, where particular pattern effects are specifically required by the customer. These are worked with a numeric control grinder, where a preset program is followed, as per the customer’s requests. Usually, the very deep structures, are coated with polymer.

Hardened steel.

Stellite welding.

Disposable type.