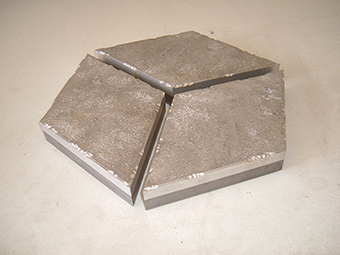

The availability of advanced graphic or manufacturing systems such as, for example, the scanning laser for the detection of surfaces and their faithful reproduction on a sample, the software for three-dimensional graphic modelling and high speed grinders, leads to the fast preparation of a prototype of any mould matrix type. Chalk prototypes can also be made with a structured surface and even three-dimensional patterns. A die of Zn+Al+Mg alloy can then be made, thus creating a moulding template. All these techniques at our disposal provide all the necessary instruments for the production of the tile, from its conception to the design and finally to its pressing.

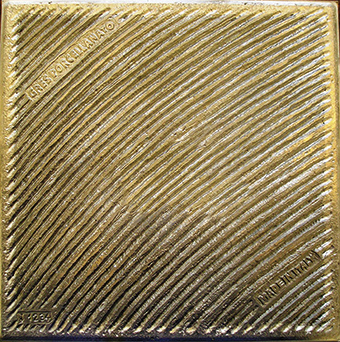

Removable logo punches and press.

Removable ceramic logos.

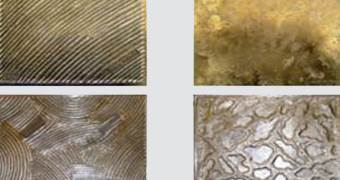

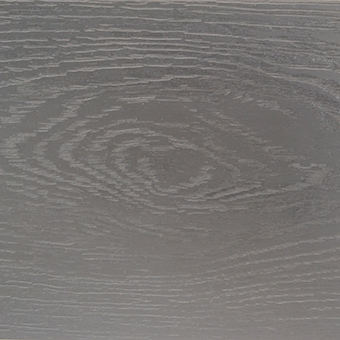

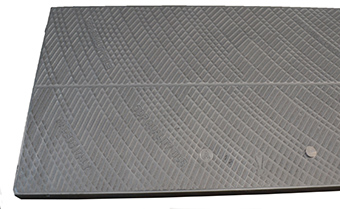

Pattern working on Customer’s request.