Materials and working life

The “T-EVO” punch is made from the best European steel and bonded together with a special welding for a very high resistance to wear, hence for a longer working life of the same.

Reliability

Contrary to traditional isostatic punches, the “Sandwich” concept of the “T-EVO” punch entirely removes the problems tied to breakages, since powder never comes in direct contact with the isostatic chamber as this is protected by the rubber membrane and by the above standing interchangeable punch.

Uniformity of pressure and density

Through compensation of a single isostatic chamber the “TREBAX 2” punch applies to the product a single and uniformly spread pressing density, with the consequential uniform absorption of the enamel application.

Marketing

As it features a single isostatic chamber, which removes all geometrical ties connected with underside design, it can best underline all technical and esthetical aspects. There will not be any depression or undulations. An added value for the product in esthetical terms.

Replacement

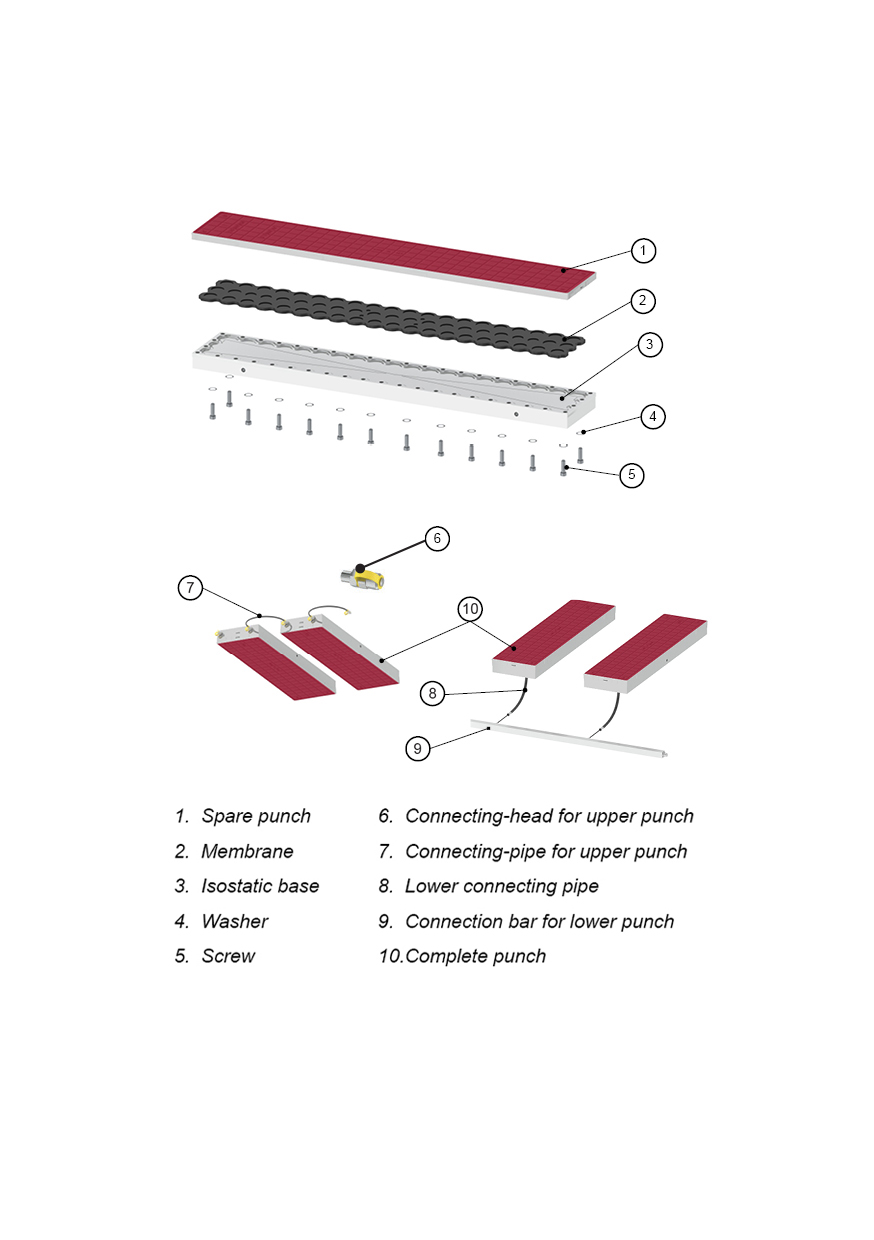

The “T-EVO” punch are of the throw away type: when first supplied, assembled punches and isostatic bases complete of membrane will be supplied. Once worn down, only the interchangeable punches will be replaced, but the isostatic block will remain the same. In case of load application faults, which can entail a loss of oil, contrary to traditional isostatic punches for which replacement is required, the “T-EVO” punch will only require the changing of the interchangeable membrane and the punch will be re-installed and used until its complete wearing out. This obviously means very conspicuous savings.

Reduce your costs

The exceptional robustness and the particular functioning concept of the Trebax punches will enable the creation of very deep cavities inside the tiles, with the ensuing saving on raw materials: up to 3 Kg of powder per square meter. For ex.: on a 45x45 format, by increasing the underside grooves by only 0,5 mm, a weight reduction per tile of 225 gr is obtained. On the basis of a production of 5000 square meters per day, the quantity of saved powder per year will be around 16.800 hundredweights (1.680 tons). A very large saving indeed. Without obviously taking into consideration the saving on expenses for row materials transportation and tiles. As the “T-EVO” punch consists of 3 different parts – punch, membrane, isostatic base – for each production type different versions can be designed, as well as for the solution of any possible defect on the same tile.

Technical and economical advantages

1. HIGH COMPENSATION / SQUARENESS

2. RELIABILITY OF THE ISOSTATIC OIL CHAMBER

3. NO TRANSPARENCY EFFECT

4. UNIFORMITY OF PRESSURE AND DENSITY

5. PLANARITY

6. CALIBER

7. THICKNESS OF TILE UNIFORMLY ACROSS

THE SURFACE, SO EVEN IN SIZES SUITABLE

FOR CUTTING IN THE SMALLER SIZES OR

PLANKS

8. BODY TILE SAVING

9. SUITABLE FOR SMALL AND BIG SIZES TILE

10. SUITABLE FOR EACH TYPE OF BODY TILE