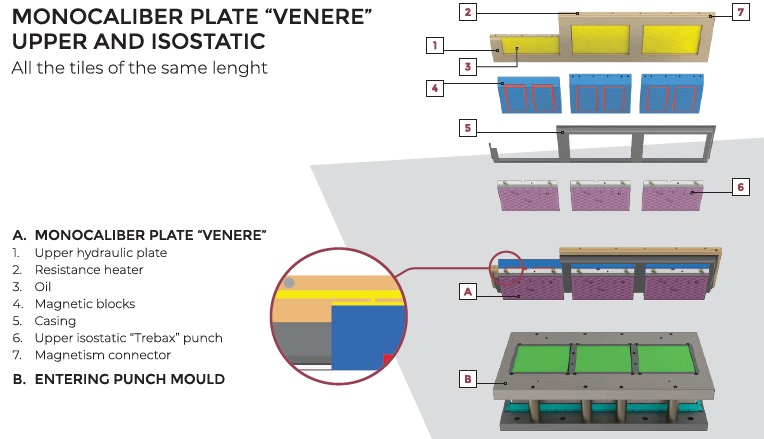

Created because

The evolution of the pressing technique, in terms of finished product, has presented problems that moulds and isostatic punches of the traditional type cannot solve. This has posed the need to create a product, which,in conjunction with the “trebax” isostatic punches, could solve the many production problems.

Structure and materials

The ISOSTATIC MAGNETIC PLATE consists of an upper hydraulic plate, inside of which lodgings are created to accommodate the magnetic blocks. The lodgings are interconnected through deep nesting holes inside the plate, for the flowing of the oil between the cavities. The oil is retained by a hydraulically tight system, already widely tested. Contrary to normal magnetic plates, the ISOSTATIC MAGNETIC PLATE is made from hardened material, highly resistant to pressure and to the deformations caused by pressing.

Reliability

The holding strength and oil retention capability of the system is extremely reliable and entirely internal. The isostatic magnetic plate together with the isostatic Trebax punches do away with the connecting pipes for the punches, thus obviously avoiding the breaking of the same, the breaking of the isostatic punches and the consequential production of out of square material, hence destined to be downgraded.

Uniformity of pressure and density

The telescopic and independent blocks consent the uniformity of density between one cavity and the next of the mould and therefore obtaining many advantages on the finished product. This also safeguards the press since pressure strength is evenly spread out and well balanced. The isostatic magnetic plate together with the isostatic Trebax punches are conducive to achieving a proper squaring and gauging, since: the oil of the isostatic punch works in the inside of the same to achieve an equal length of the sides of the single tile (squaring) and the oil of the isostatic magnetic plate works in the inside of the same to achieve equal lengths between the various cavities (gauge). On a mould with 4 cavities we have the certainty that all 4 tiles, in view of the uniformity of the applied pressure, though featuring very deep reliefs and differing from one another, will enter in the same box, as they are of the same length.

Reduce your costs! Reduce your store!

What does it mean, in terms of costs, to produce a single gauge? It means been able to produce the required volume only, necessary for the clearing of the Customer’s order, without producing any surplus that will not be sold, but which will be stocked in the store, with the ensuing unnecessary increase of value.

Technical and economical advantages

1. Monogauge. A lesser quantity of different gauges in store will inevitably correspond to important economic savings.

2. Connecting pipes of the isostatic punches no longer required, thus avoiding breakages of the same, possible oil leaks and related loss of production (downtime).

3. Pressure uniformity throughout the cavities.

4. Removal of possible expansion cracks.

5. Individual magnetization and de-magnetization of every isostatic punch, with marked advantages in terms of time dedicated to the replacement and the centering of every single isostatic punch.

6. Possibility of having an electromagnetic or permanent magnetism.

7. Constant centering on a periodical basis of the isostatic punches, lesser wearing of the mould.

8. Reduction of the machine downtime, due to the centering of punches, following the displacement of the same during production.

9. Possibility to manufacture products with moulds featuring multiple rows (ex.: 32 cavities 10x10, 20 cavities 15x15, 14 cavities 20x20, 8 cavities 30x30, 6 cavities 40x40 etc.) with the peace of mind of realizing monogauge tiles.

10. Pressure uniformity throughout the cavities also means the safeguarding of the press, since the applied compression strength is evenly spread out and well balanced.

11. In case of loading problems, the oil can be removed and it will work as a normal magnetic plate, without loss of production.

12. Possibility of manufacturing tiles featuring very deep reliefs and differing from one another, with the certainty of placing the tiles in the same box.

13. Production of materials with always differing drawings and structures and still using a single commercial vehicle.